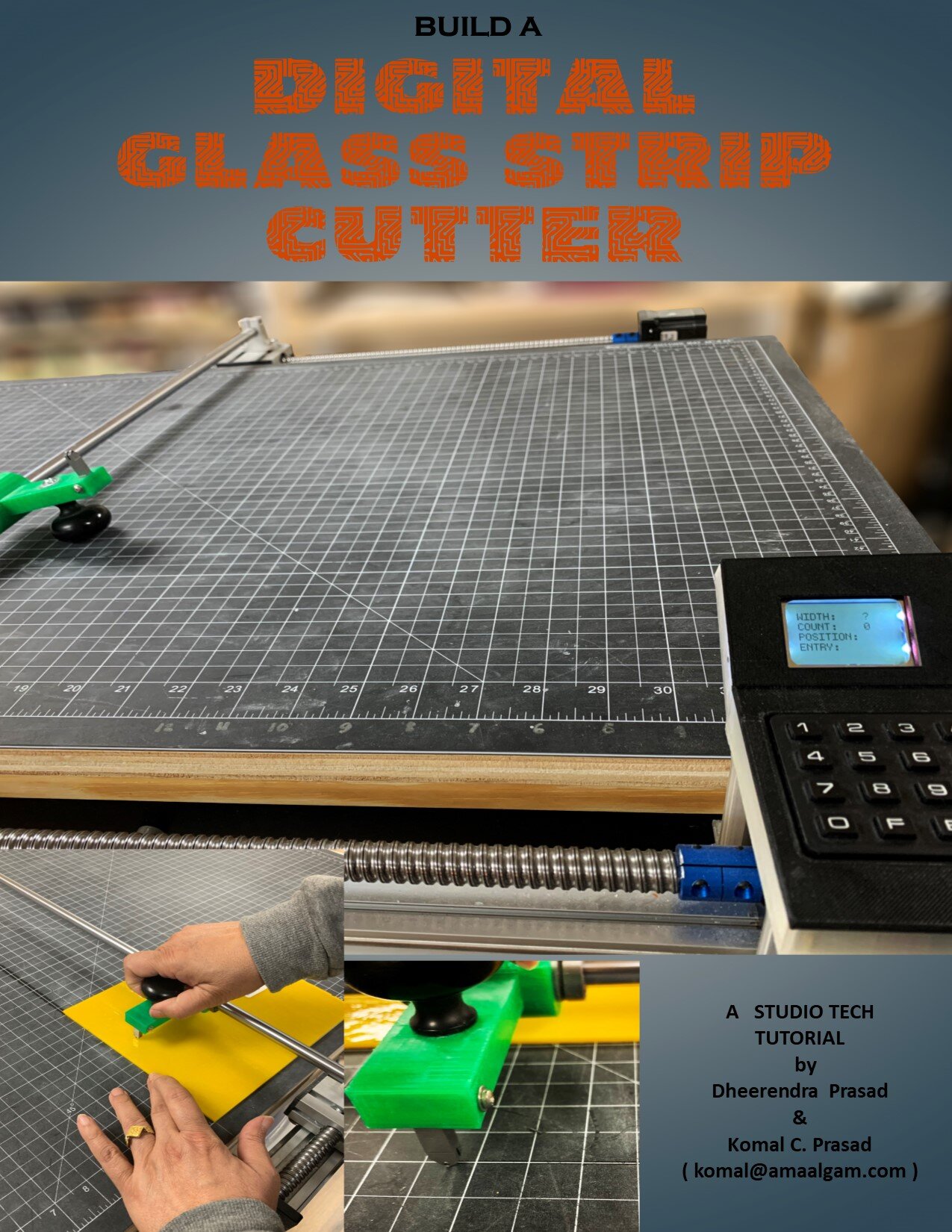

Amaalgam Digital Glass Strip Cutter

A Cool Project for your studio and a high precision unique tool for a lifetime!

A Project that started when my husband saw me painstakingly mark and move the glass to cut strips !

He said he could design a cutter that would advance itself from score to score rather than me having to move and mark the glass. Even though I forgot about it, he did not, and from his penchant for engineering things, this easy to use cutter was born. I have now used it for over two years and it has worked flawlessly. After my fellow ‘glassies’ expressed interest in it, he agreed to write a tutorial, so others could benefit from this tool/gadget.

Features of cutter:

Precise

Fast and efficient

No need to mark or erase marks from glass

No need to move/re-position the glass between cuts.

Keeps a count of the number of strips cut.

Strip widths can be changed on the fly, again, without having to move the glass.

Easy to follow

The tutorial— which took several weekends to prepare— is illustrated profusely with engineering diagrams and high quality artwork to illustrate every step. I am not a technical person, yet I was easily able to build a second cutter, following the tutorial to ensure that the steps were easy to follow for anyone.

While we do not provide a kit for logistical reasons, there are links to every part readily available from online sellers - researched to find you the lowest cost options. If you have difficulty with sourcing a part where you live (unlikely as these are very common parts) contact us for substitution ideas.

One of the many detailed illustrations that guide the build.

All headers are pre-soldered to this board—all you do is slide in the components.

Even easier with a custom Printed Circuit Board

In order to make the build foolproof and to eliminate almost all soldering and wiring a PCB has been designed to support you. This makes the whole project much simpler for those who want the convenience. The tutorial however describes the ‘scratch build’ in detail for those who want to enjoy the whole process. The PCB option will not increase project costs for you as it eliminates many of the components in the parts list.

The controller code is already provided to you and has been tested extensively.

Note: A completely assembled controller, along with the case, is available for purchase and reduces this project to just some mechanical mounting of parts, and a dozen screwdriver based wire hookups! The cost of assembly has been kept at the lowest possible.

A number of 3D printed parts already made for you

Cut head for the cutter comes with the linear bearing installed. All you will need is a TOYO TC10 / TC17V Cut head.

The tutorial comes with a complete set of files for 3D printable parts that make the build both possible, as well as secure key components safely and ergonomically. However if you do not have access to a 3D printer you may buy those parts from Amaalgam. All parts are printed on an industry grade 3D printer and are durable and precise.

Available in two versions, for the Toyo TC10 and the Toyo Tap Cutter TC17 head.

Curious?

This brief video shows you how the cutter works in the studio. For brevity of the video, I have shown just a few scores. And I have gone extra slow to show the process. But you can work much faster and can make almost 20 scores before you need to break the strips. The speed of the scores reduces the time between score and break, and overcoming the ‘healing’ of the glass.

Ready to build your own Digital Strip Cutter?

The tutorial is in the tutorial section and the 3D parts are under Glass Supplies.